6-20 个字符(仅限字母加数字)

密码不一致

Understanding Temperature Sensors: A Key to Smart Technology

In today’s fast-paced world, technology is advancing at a breakneck speed. One of the fundamental aspects of this advancement is the ability to gather data from our surroundings. One device that plays a crucial role in this is the temperature sensor. In particular, the motor sensor de temperatura (temperature sensor for motors) is an essential component in various applications, from industrial machinery to everyday home appliances. This blog will explore the importance of temperature sensors, how they work, their various applications, and why the motor sensor de temperatura is vital in today’s technological landscape.

What Are Temperature Sensors?

Temperature sensors are devices that measure the degree of heat or cold in an environment. They convert thermal energy into a readable output, usually in the form of voltage or current, which can then be interpreted by a control system or displayed on a screen. There are various types of temperature sensors, including thermocouples, thermistors, infrared sensors, and, importantly, motor temperature sensors.

The Science Behind Temperature Sensors

The functioning of temperature sensors is based on the principles of thermodynamics. At its core, a temperature sensor reacts to temperature changes in its environment. For example, when a thermocouple is heated, it produces a small voltage that is proportional to the temperature difference between its two junctions. This voltage can be measured and converted into a temperature reading.

Similarly, a thermistor—a type of resistor that changes its resistance with temperature—can provide accurate readings by measuring changes in electrical resistance. Each type of sensor has its advantages and limitations, making them suitable for different applications.

The Role of the Motor Sensor de Temperatura

Why Temperature Matters in Motors

Motors are at the heart of countless machines and systems, from electric vehicles to household appliances. They generate heat during operation due to friction and electrical resistance. If the temperature of a motor rises too high, it can lead to failures, decreased efficiency, and, in severe cases, catastrophic damage. This is where the motor sensor de temperatura comes into play.

Functionality of the Motor Sensor de Temperatura

A motor temperature sensor continuously monitors the temperature of a motor. When the sensor detects that the temperature has exceeded a pre-set threshold, it sends a signal to the control system. This system can then take appropriate action, such as shutting down the motor, activating cooling systems, or alerting operators about potential issues.

Types of Motor Temperature Sensors

There are several types of temperature sensors used specifically for motors, including:

Thermocouples: These are widely used in industrial applications due to their wide temperature range and durability. They can withstand harsh environments and provide accurate readings even under extreme conditions.

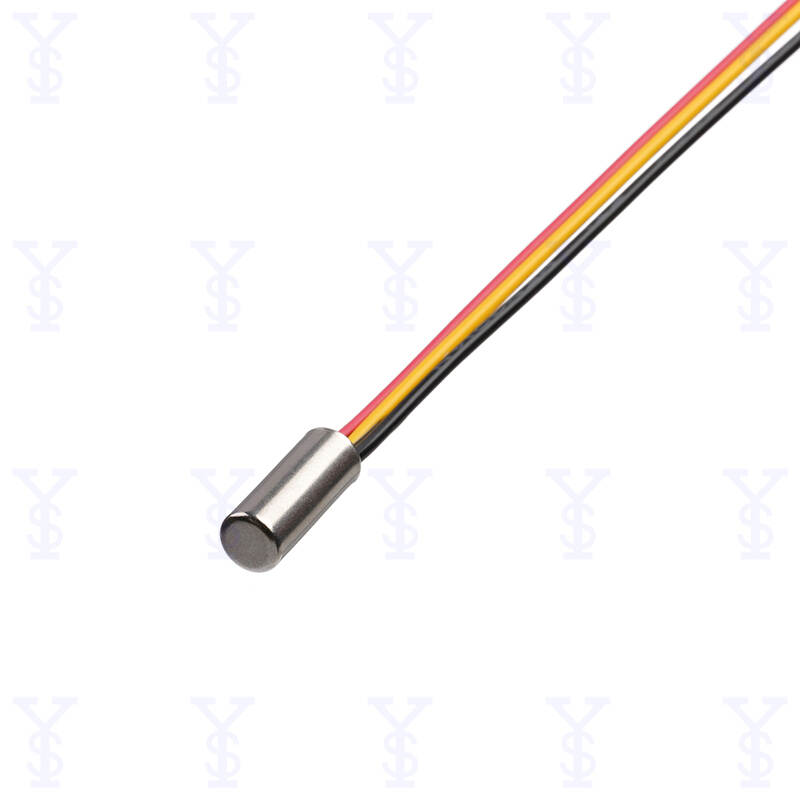

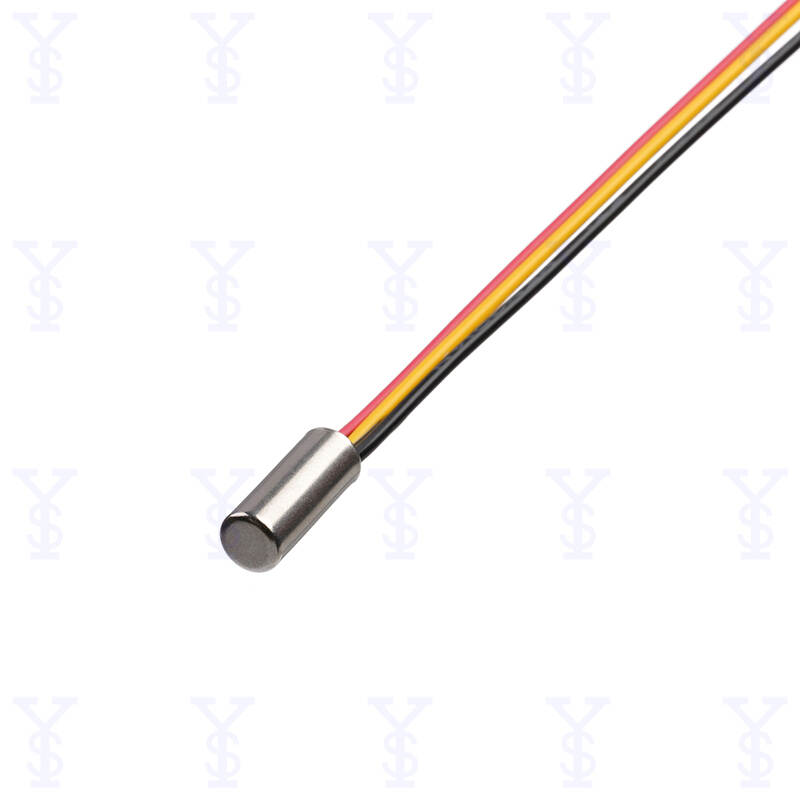

Thermistors: These are more sensitive than thermocouples and are often used in consumer electronics. They are smaller and provide rapid responses to temperature changes, making them ideal for applications where quick feedback is crucial.

Infrared Sensors: These non-contact sensors measure the thermal radiation emitted by an object, allowing for temperature monitoring without direct contact. They are particularly useful in scenarios where the motor may be in a difficult-to-reach location.

Bimetallic Sensors: These sensors consist of two different metals bonded together. When heated, the metals expand at different rates, causing the sensor to bend and activate a switch. They are often used in simple applications where precise temperature control is not critical.

Applications of Motor Sensors de Temperatura

Industrial Machinery

In manufacturing and industrial settings, motors are often used to power conveyor belts, robotic arms, and various automated systems. The motor sensor de temperatura helps prevent overheating, which can cause production delays and costly repairs. By ensuring motors operate within safe temperature limits, companies can maintain productivity and avoid downtime.

Electric Vehicles

As electric vehicles (EVs) become more prevalent, the role of temperature sensors in motors is increasingly important. The efficiency of electric motors can be heavily affected by temperature fluctuations. The motor sensor de temperatura helps monitor the performance of these motors, ensuring they remain within optimal operating temperatures. This not only improves efficiency but also extends the lifespan of the vehicle’s components.

HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems rely heavily on motors to function effectively. The motor sensor de temperatura is crucial in these systems to ensure that the motors do not overheat, which could lead to system failures and increased energy consumption. By continuously monitoring temperature, these sensors help maintain comfortable indoor environments while maximizing energy efficiency.

Home Appliances

In our daily lives, we encounter various home appliances that utilize motors, such as refrigerators, washing machines, and fans. The motor sensor de temperatura helps regulate these appliances, ensuring they operate efficiently and safely. For example, in refrigerators, the motor sensor can prevent the compressor from overheating, maintaining optimal cooling temperatures and preventing food spoilage.

The Benefits of Using Motor Temperature Sensors

Increased Safety

One of the primary advantages of incorporating motor sensors de temperatura into machinery is the enhancement of safety. By continuously monitoring temperature, these sensors can prevent overheating, reducing the risk of fires or other dangerous failures. This is particularly critical in industrial settings, where the consequences of overheating can be catastrophic.

Improved Efficiency

Efficiency is vital in both industrial processes and consumer products. A motor that runs at optimal temperatures will consume less energy and perform better. The motor sensor de temperatura plays a crucial role in achieving this efficiency by ensuring that the motor does not operate beyond its ideal temperature range.

Cost Savings

Preventing motor failure through temperature monitoring can lead to significant cost savings. The expense of repairing or replacing a motor can be substantial, not to mention the potential costs associated with downtime in industrial settings. By using motor sensors to maintain safe operating temperatures, businesses can avoid these costs and enhance their bottom line.

Extended Equipment Lifespan

Proper temperature regulation can extend the lifespan of motors and other equipment. Motors that operate within safe temperature limits experience less wear and tear, resulting in fewer breakdowns and longer service life. This is particularly important in industries where equipment replacement costs are high.

Challenges and Future Developments

Sensor Accuracy and Calibration

While motor sensors de temperatura are invaluable, ensuring their accuracy can be a challenge. Regular calibration is necessary to maintain precise measurements. If a sensor provides incorrect readings, it could lead to improper functioning of the motor, causing either unnecessary shutdowns or potential overheating.

Environmental Factors

Temperature sensors can be affected by environmental factors such as humidity, dust, and electromagnetic interference. These factors can skew readings and impact performance. Future developments in sensor technology aim to create more robust sensors that can withstand adverse conditions while providing reliable data.

The Rise of Smart Technology

As the Internet of Things (IoT) continues to expand, temperature sensors are becoming increasingly integrated into smart devices. Motor sensors de temperatura are now being designed to communicate wirelessly with control systems, allowing for remote monitoring and real-time data analysis. This advancement enables proactive maintenance and further enhances efficiency and safety.

Conclusion

In summary, the motor sensor de temperatura is a vital component in modern technology. Its ability to monitor temperature in motors ensures safety, efficiency, and longevity across various applications. As technology advances, the role of these sensors will continue to evolve, becoming even more integral to smart systems and the overall functioning of our machinery.

Whether in industrial settings, electric vehicles, or home appliances, the importance of temperature sensors cannot be overstated. They are the unsung heroes that help maintain the balance between performance and safety, ultimately enhancing our daily lives and driving technological progress. As we move forward, investing in better and more reliable temperature sensing technology will be crucial in building a safer and more efficient future.